Breakthrough technology to extend the preservation of fruits, vegetables, flowers and mushrooms

Breakthrough technology to extend the preservation of fruits, vegetables, flowers and mushrooms

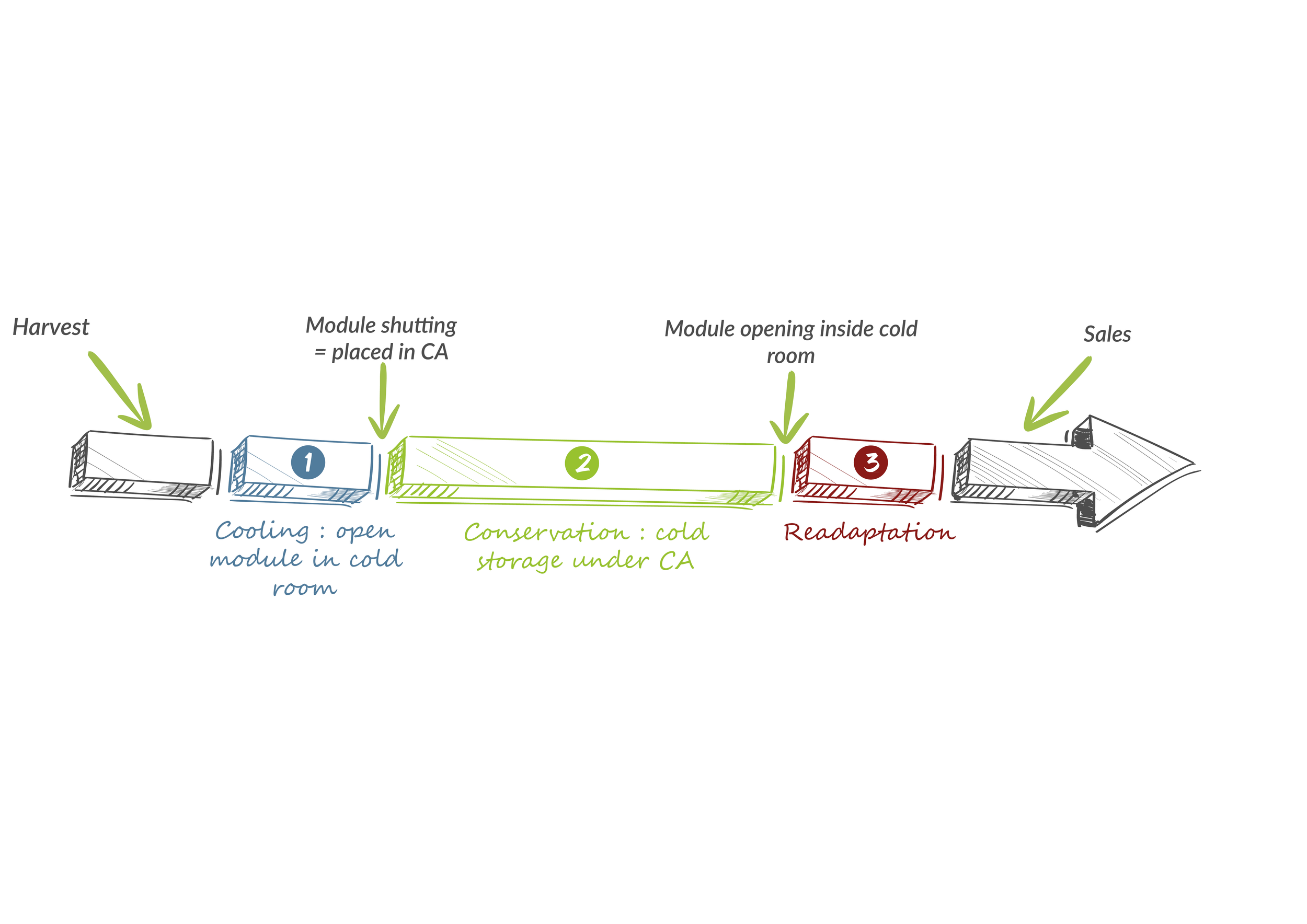

Storage Process Using the JMT Module

The controlled atmosphere in the bins is a completely natural process. There are no additional gases or modifications required since the produce in the module is able to naturally absorb oxygen once the modules are sealed.

The atmosphere is stabilized by a passive diffusion through the 6 patented membranes of the Tiempo Cap lids. The membranes release the CO2 to avoid intoxication and allow minimal amounts of O2 into the bin, maintaining a low level of oxygen for respiration.

Because different types of produce need different gas exchange levels, the amount of gas exchange can easily be reduced or increased to reach the optimum preservation standards thanks to red (Tiempo Cap 6) cap that stop the flow of gasses. Thus, the same bin can be used for various types of produce by adding or removing caps over the membranes on the lid. Adjusting the lid is a quick and easy process.

optimum module conservation with obstructing red caps

Produce can now be stored much longer inside your cooler or reefer. Thanks to the controlled atmosphere, you are able to multiply by 2 or more the time your produce can be stored fresh. Each bin is independent and designed to be stacked; they can be stacked up to nine heights.

When the bin is closed, the relative humidity inside it remains at nearly 100%, which prevents significant weight loss during storage or transport. The water retention is fundamental for preservation and to maintain the freshness of fruits, vegetables, flowers or mushrooms. With the JMT bins, product remains fresh, for example apples lose less than 1.5% of their weight after 6 months of storage.

Closing and opening the bin is a very easy process, done by hand and takes less than 10 seconds.

For successful storage

The product must be harvested at the appropriate ripening stage for long storage, maintaining the quality for controlled atmosphere storage.

Once the produce has been harvested, let it first cool down before closing the bin so that the produce core reaches the storage temperature.

Clip the lid onto the bin to seal the bin completely. The storage process can then begin.

Routinely measure the oxygen and carbon dioxide levels to monitor the storage conditions and keep track of levels using a table. This can be done with the Tiempo Test Silver gas analyzer.

Before selling the product, a re-adaptation phase is necessary. The lid must be opened and the produce must be kept in cold conditions one day before sales.

Modules installation inside a cold room